- info@vampoly.com

- +91-98480-50625

- +91-77990-57575

At VAM POLY PLAST, we work closely with mining companies that depend on reliable and efficient screening systems to keep their operations running smoothly. In mining and mineral processing, accurate material separation is critical for productivity, equipment life, and overall profitability.

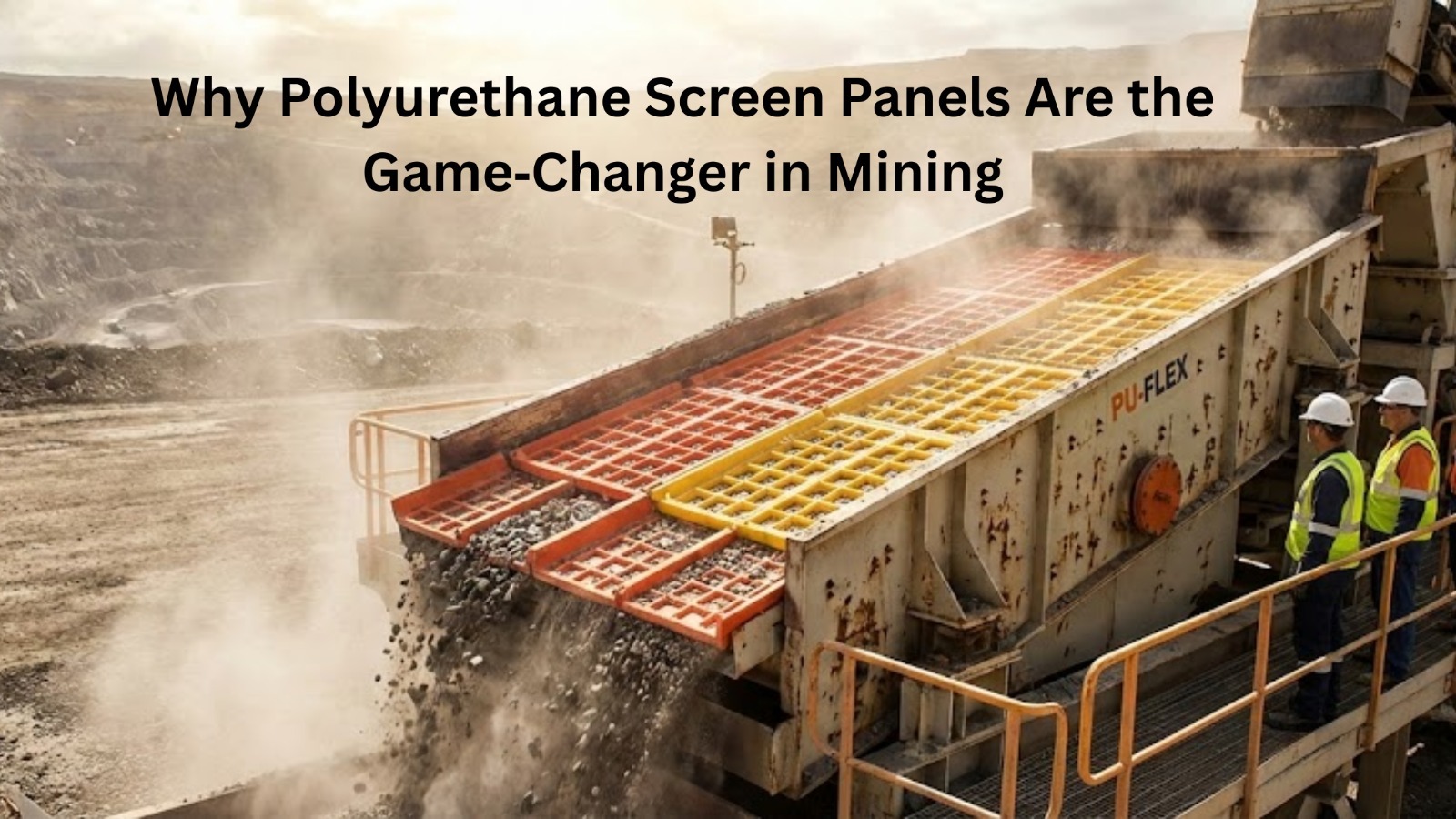

Over the years, we have seen the limitations of traditional screening materials such as wire mesh and rubber panels. Frequent breakdowns, high maintenance, and inconsistent screening results often create operational challenges. This is where polyurethane screen panels for mining have truly changed the game.

With our advanced polyurethane screening solutions, we help mining operations improve efficiency, reduce downtime, and extend equipment life.

Polyurethane screen panels, commonly known as PU screen panels,are manufactured using high-quality elastomeric polyurethane materials. These panels are installed on vibrating screens to separate minerals based on size during mining and mineral processing operations.

Compared to metal and rubber screens, polyurethane vibrating screen panels offer an ideal balance of strength, flexibility, and wear resistance. This makes them highly suitable for the demanding and abrasive conditions found in mining environments.

1. Exceptional Wear Resistance

Mining materials such as ores, coal, gravel, and crushed stone are highly abrasive. Traditional screens wear out quickly under constant impact and friction.

Our polyurethane screen panels for mining are designed with superior abrasion resistance, allowing them to last significantly longer than wire mesh or rubber alternatives. This means:

2. Improved Screening Efficiency

One major advantage of polyurethane is its ability to maintain consistent aperture sizes over time. Unlike metal screens that stretch or deform, PU panels retain their shape even under heavy vibration.

This results in:

For mining operations, better screening efficiency directly impacts product quality and profitability.

3. Reduced Downtime and Maintenance

Unplanned downtime is one of the biggest cost factors in mining operations. Our polyurethane screen panels are engineered to withstand continuous vibration and heavy impact without cracking or failure.

By choosing polyurethane screening solutions from VAM POLY PLAST, mining companies can significantly reduce:

4. Noise and Vibration Reduction

Mining sites are naturally high-noise environments. Polyurethane has excellent vibration-absorbing properties, which helps reduce operational noise compared to metal screens.

Lower noise and vibration levels:

5. Corrosion and Chemical Resistance

Metal screen panels are prone to corrosion, especially in wet screening or chemically aggressive conditions. Polyurethane is resistant to water, chemicals, and temperature variations.

This makes our polyurethane vibrating screen panels suitable for:

Although polyurethane screen panels may have a slightly higher initial cost than wire mesh, they deliver substantial long-term savings. Longer service life, reduced downtime, and minimal maintenance make PU panels a cost-effective mining solution

Mining operations that switch to polyurethane often experience:

At VAM POLY PLAST, we understand that no two mining operations are the same. As a trusted PU screen panels manufacturer, we provide fully customized polyurethane screen panels in various:

Our customized solutions ensure:

Our polyurethane screen panels are widely used across various mining and mineral processing applications, including:

Their versatility makes them ideal for both primary and secondary screening stages.

At VAM POLY PLAST,we are committed to delivering reliable and high-performance polyurethane screening solutions for the mining industry. Our products are manufactured using premium raw materials and advanced production techniques to ensure consistent quality.

What sets us apart:

We focus on helping mining companies improve productivity while minimizing operational challenges.

The mining industry demands durable, efficient, and reliable screening systems to stay competitive. Polyurethane screen panels for mining have proven to be a future-ready solution by offering superior wear resistance, reduced downtime, improved screening efficiency, and long-term cost savings.

By choosing polyurethane vibrating screen panels from VAM POLY PLAST mining operators can enhance performance, reduce maintenance issues, and achieve consistent results in demanding environments.