- info@vampoly.com

- +91-98480-50625

- +91-77990-57575

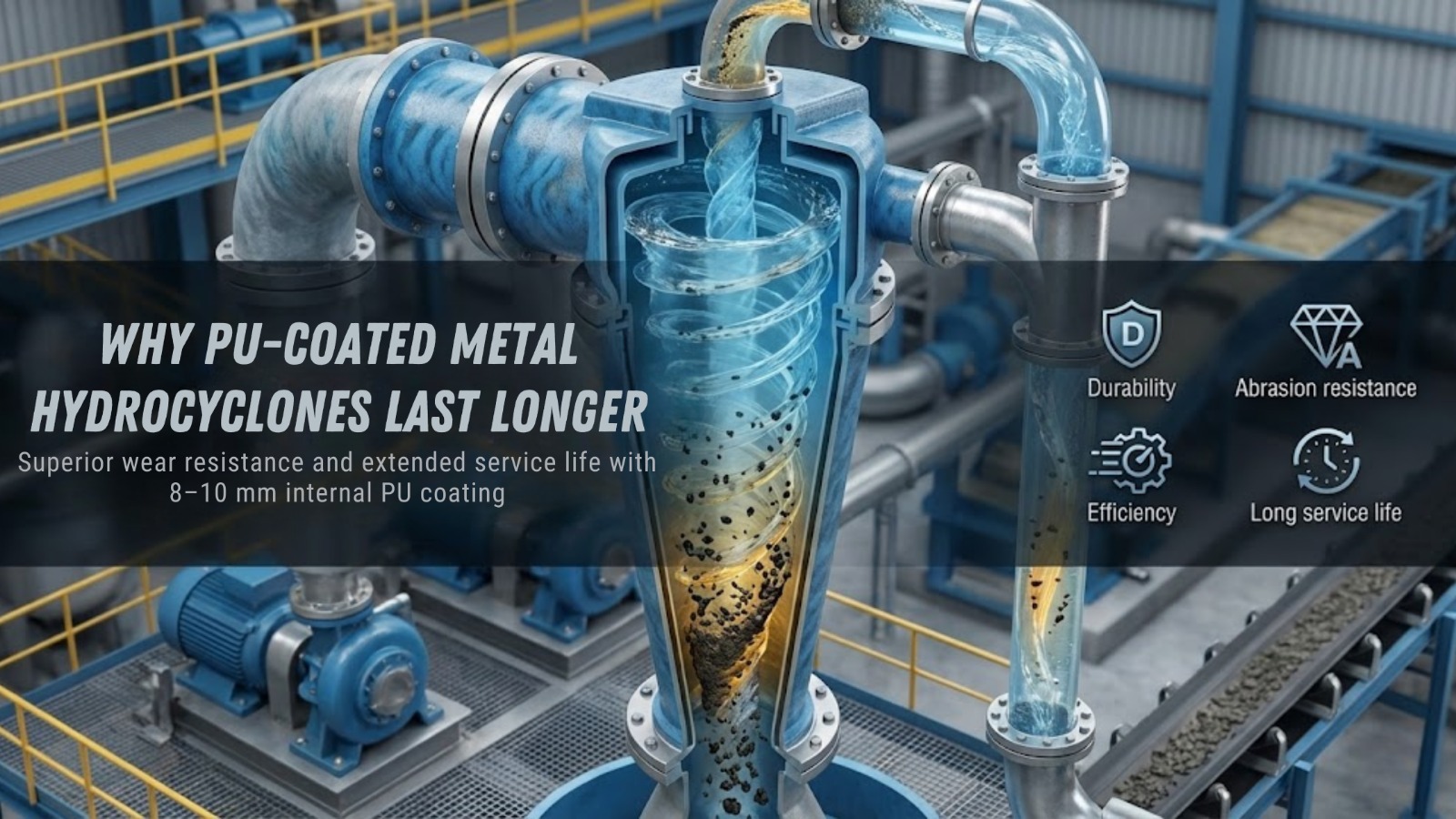

At VAM POLY PLAST, we understand that in industries like mining and mineral processing, equipment performance directly affects productivity and operating costs. One of the most critical components in these processes is the hydrocyclone. Used for separating solids from liquids, hydrocyclones must handle extreme pressure, abrasive slurries, and continuous operation.

That’s why our PU hydrocyclones are engineered to outperform traditional materials such as metal and rubber. With superior durability, efficiency, and long service life, our solutions are designed to deliver reliable performance in the most demanding industrial environments.

Our hydrocyclones are a key part of industrial hydrocyclone equipment used for classification, desliming, and slurry separation. We supply solutions for:

We focus on material selection and precision engineering because we know how harsh these operating conditions can be.

While metal hydrocyclones are strong, we’ve seen their limitations in real-world applications:

Rubber offers better abrasion resistance than metal, but it still has drawbacks:

These challenges increase maintenance costs and disrupt production.

One of the biggest advantages of our high durability hydrocyclones is their outstanding abrasion resistance. The polyurethane we use withstands sharp particles and high flow rates far better than traditional materials.

This makes our hydrocyclones ideal for the mining industry, where abrasive slurries are part of daily operations.

Our PU hydrocyclones are built to last. Their resistance to erosion and deformation allows them to maintain performance for extended periods.

For clients using hydrocyclones for mineral processing, this means fewer replacements, reduced downtime, and lower overall operating costs.

Despite their strength, our PU hydrocyclones are lightweight, which offers several advantages:

This combination of strength and weight efficiency is a key reason our customers prefer PU over metal or rubber.

Unlike metal components, our polyurethane hydrocyclones do not corrode. They perform reliably even in environments exposed to moisture, chemicals, and varying pH levels.

This makes our products ideal for long-term use in wet and chemically aggressive processing plants.

Our PU hydrocyclones retain their internal profile even after prolonged use. This ensures:

For mineral processing plants, this consistency is essential for maintaining process efficiency and product standards.

Because of their durability, our PU hydrocyclones require minimal maintenance. This results in:

Over time, this makes our PU hydrocyclones a highly cost-effective investment.

We supply PU hydrocyclones for a wide range of applications, including:

Our solutions are suitable for both small-scale installations and large industrial operations.

VAM POLY PLAST we specialize in polyurethane-based industrial solutions. Our expertise in PU molding and engineering allows us to manufacture hydrocyclones that meet the highest industry standards.

What Sets Us Apart:

When it comes to durability, efficiency, and long-term cost savings, our PU hydrocyclones clearly outperform traditional materials. With superior abrasion resistance, excellent corrosion protection, and extended service life, they are the smart choice for modern industrial hydrocyclone equipment.

For industries relying on hydrocyclones for mining and mineral processing, Vam Poly Plast’s PU hydrocyclones deliver dependable performance and support sustainable operational success.