- info@vampoly.com

- +91-98480-50625

- +91-77990-57575

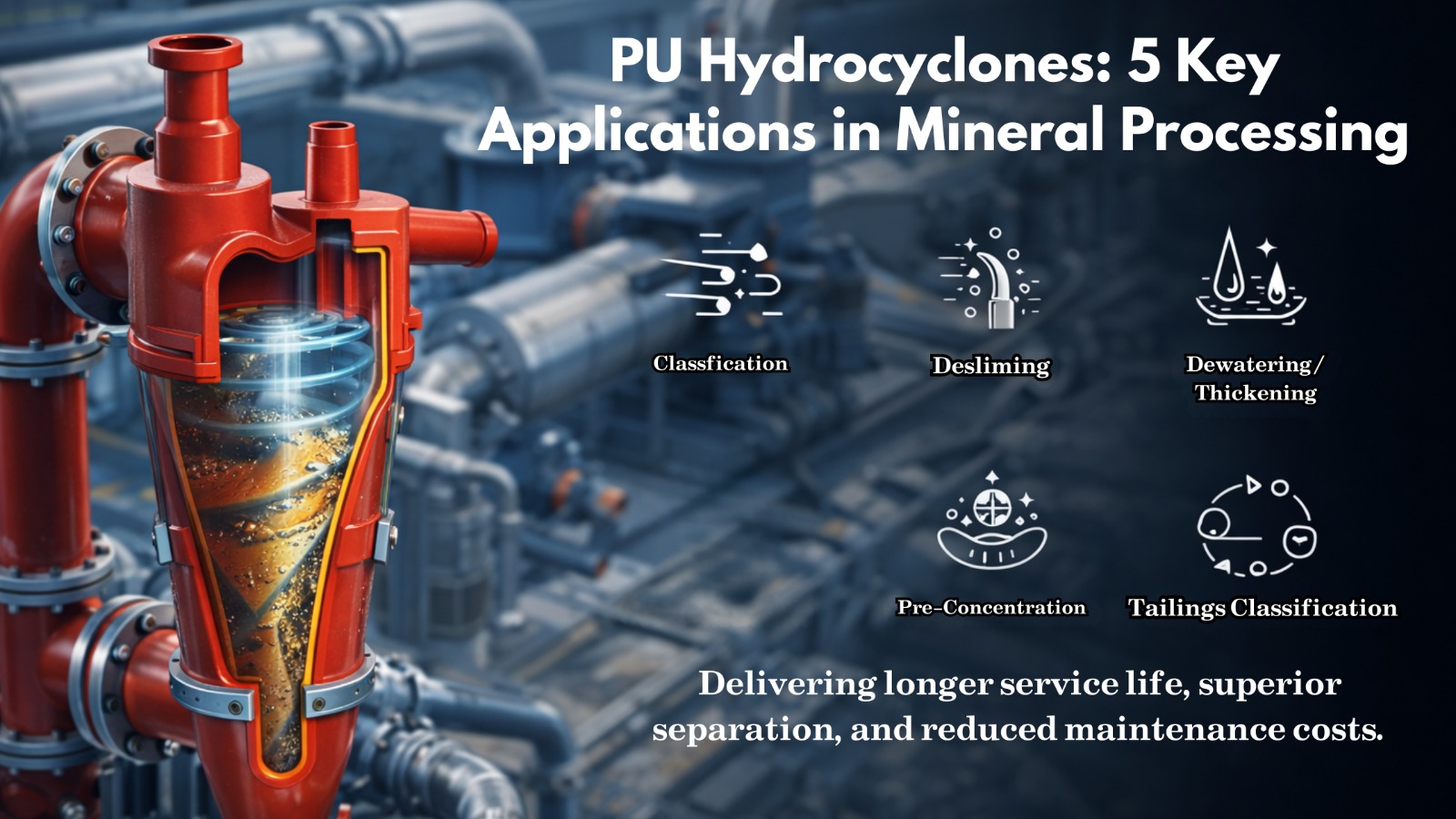

In today’s mineral processing industry, efficiency, durability, and cost control are more important than ever. As ores become more complex and operating conditions harsher, mining companies need equipment that can withstand continuous wear while delivering consistent performance. This is where PU hydrocyclones have become an essential solution.

Known for their high wear resistance and long service life, high-performance polyurethane hydrocyclones are widely used across mineral processing plants. As a best PU hydrocyclone manufacturer Vam Poly Plast provides advanced hydrocyclone solutions designed to improve separation efficiency and reduce maintenance costs.

Let’s explore the top 5 applications of PU hydrocyclones in mineral processing and why they are indispensable in modern mining operations.

One of the most common applications of PU hydrocyclones is particle size classification. In mineral processing, accurate separation of fine and coarse particles is crucial to optimize downstream processes such as flotation, gravity separation, or leaching.

PU hydrocyclones efficiently classify slurry based on particle size and density using centrifugal force. Their smooth internal surface and precision-engineered design help maintain stable cut sizes, even under fluctuating feed conditions.

Thanks to their abrasion resistance, durable hydrocyclone liners for mining made from polyurethane ensure consistent classification over long operational cycles. This makes PU hydrocyclones a preferred choice for plants aiming to improve product quality and throughput.

Desliming is an essential step in mineral processing, especially before flotation. Excessive slimes can reduce recovery rates and interfere with reagent performance. PU hydrocyclones are widely used to remove ultra-fine particles from mineral slurries before further processing.

Compared to rubber or metal alternatives,high-performance polyurethane hydrocyclones offer superior resistance to fine particle abrasion, which is common in desliming circuits. Their flexibility also helps absorb impact, reducing the risk of cracking or premature failure.

As a trusted mining hydrocyclone equipment supplier, Vam Poly Plast designs PU hydrocyclones that deliver efficient desliming while minimizing downtime and maintenance costs.

PU hydrocyclones play a vital role in thickening and dewatering applications. By separating solids from liquids, they help concentrate mineral slurries and reduce the load on thickeners, filters, and tailings systems.

In these applications, hydrocyclones are exposed to continuous abrasion and high-pressure flows. Polyurethane liners outperform traditional materials by offering longer service life and stable performance.

Using durable hydrocyclone liners for mining ensures improved water recovery, reduced waste volume, and lower operating costs. This makes PU hydrocyclones an eco-friendly and cost-effective solution for modern mineral processing plants.

Grinding circuits demand precise control over particle size to prevent over-grinding and excessive energy consumption. PU hydrocyclones are commonly used as classifiers in closed grinding circuits to return coarse material to the mill while allowing fine particles to move forward.

Because of their dimensional stability and wear resistance, high-performance polyurethane hydrocyclones maintain consistent separation efficiency over time. This results in better grinding control, reduced power consumption, and improved overall plant performance.

As the best PU hydrocyclone manufacturer, Vam Poly Plast ensures each unit is engineered to deliver reliable results even in high-throughput grinding applications.

Effective tailings management is critical for environmental compliance and sustainable mining operations. PU hydrocyclones are widely used to classify tailings, recover valuable minerals, and improve water recycling.

Polyurethane hydrocyclones are especially suited for tailings applications due to their resistance to chemical corrosion, abrasion, and fluctuating operating conditions. Their long service life reduces replacement frequency, helping mining companies lower operational expenses.

As a reliable mining hydrocyclone equipment supplier, Vam Poly Plast provides customized PU hydrocyclone solutions that support efficient tailings handling and responsible waste management.

Choosing the right hydrocyclone partner is just as important as selecting the right equipment. VAM POLY PLAST is recognized as a best PU hydrocyclone manufacturer, offering solutions that combine durability, performance, and cost efficiency.

Key Advantages:

With advanced manufacturing processes and strict quality standards, Vam Poly Plast delivers high-performance polyurethane hydrocyclones that meet the demanding requirements of mineral processing plants worldwide.

PU hydrocyclones have become an integral part of mineral processing operations due to their versatility, durability, and efficiency. From particle classification and desliming to grinding circuit optimization and tailings management, their applications continue to expand across the mining industry.

By investing in durable hydrocyclone liners for mining and partnering with an experienced mining hydrocyclone equipment supplier like Vam Poly Plast, processing plants can achieve higher productivity, lower operating costs, and long-term reliability.