- info@vampoly.com

- +91-98480-50625

- +91-77990-57575

At Vam Poly Plast,we work closely with industries that rely on wear-prone components such as rollers, seals, liners, bushes, wheels, and other critical industrial parts. One question we hear repeatedly from manufacturers and plant managers is:

Is polyurethane (PU) really better than traditional materials like rubber, metal, or plastic?

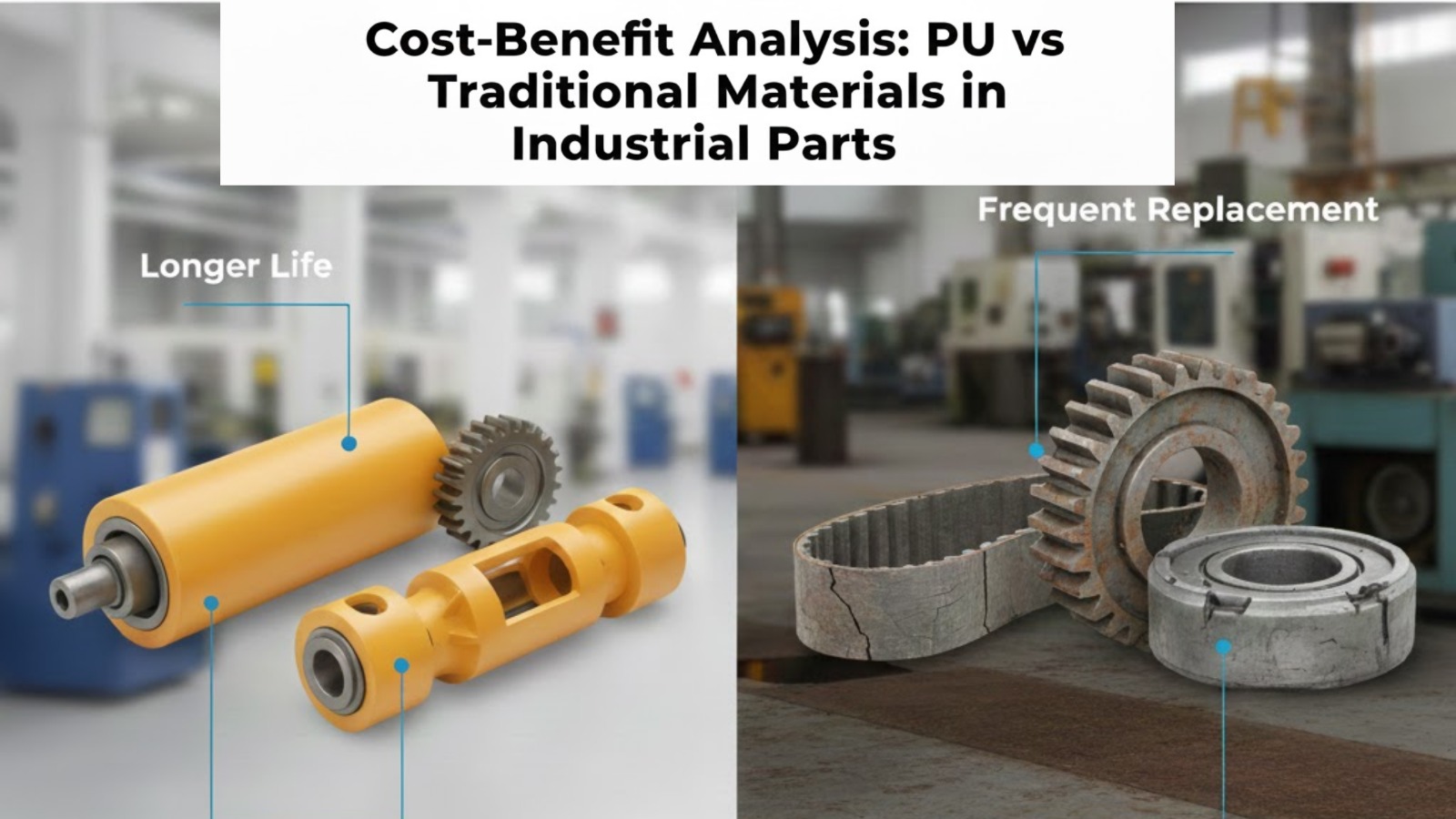

Based on our extensive experience as a polyurethane manufacturer in India, the answer is clear. This cost-benefit analysis explains how polyurethane compares with traditional materials and why more industries are choosing PU for long-term performance, durability, and return on investment.

Traditional materials such as rubber, steel, nylon, and PVC have been widely used in industrial applications for decades. While they serve basic functional needs, they often fall short in demanding operating conditions.

In our experience, these limitations lead to frequent part replacements, higher downtime, and rising maintenance expenses. Although the initial cost may be lower, the long-term operational cost is often much higher.

Polyurethane (PU) is a high-performance elastomer that combines the best properties of rubber and plastic. At Vam Poly Plast, we engineer polyurethane components that are:

Because of these properties, polyurethane has become the preferred material for industrial wear parts where long service life and consistent performance are essential.

1. Initial Cost vs Lifetime Value

At first glance, PU components may appear slightly more expensive than rubber or plastic parts. However, when we evaluate the total lifecycle cost, polyurethane proves far more economical.

This is why we consider polyurethane a cost-effective industrial material rather than a high-cost option.

2. Wear and Abrasion Resistance

Wear is one of the biggest challenges in industrial environments. Parts exposed to friction, impact, and continuous movement fail quickly if the material lacks strength.

Our polyurethane solutions offer:

This makes PU the best material for industrial wear parts such as conveyor rollers, guide rails, scraper blades, and impact components.

3. Reduced Maintenance Costs

Maintenance costs go beyond replacing parts. They include labor, machine stoppages, and lost productivity.

By switching to PU components manufactured by Vam Poly Plast, industries experience:

Over time, this results in significant savings and improved production efficiency.

4. Noise and Vibration Control

Metal components often generate excessive noise and vibration, which affects both machinery life and operator comfort. Polyurethane naturally absorbs shock and vibration.

Key advantages include:

This is especially valuable in conveyor systems and automated production lines.

5. Resistance to Chemicals and Harsh Environments

Traditional materials tend to degrade when exposed to oils, greases, moisture, and chemicals. Polyurethane performs exceptionally well in such conditions.

Our PU components are suitable for:

This environmental resistance adds to the long-term reliability and value of polyurethane.

Modern industries focus on efficiency, reliability, and sustainability. Polyurethane supports all three.

From our experience, industries choose PU because it offers:

As industrial systems evolve, the demand for high-performance polyurethane components continues to grow.

At Vam Poly Plast, we specialize in manufacturing custom polyurethane products tailored to specific industrial requirements. Our technical expertise and strict quality standards allow us to replace traditional materials with advanced PU solutions that perform better and last longer.

Our polyurethane solutions are designed to:

This makes us a trusted partner for industries seeking durable, reliable, and cost-effective polyurethane alternatives.

When we compare PU vs traditional materials in industrial parts, polyurethane clearly delivers superior value over time. While the initial investment may be slightly higher, the benefits of longer service life, reduced maintenance, and consistent performance make PU a smart and strategic choice.

For industries looking for the best material for industrial wear parts, polyurethane stands out as a proven and efficient solution. With Vam Poly Plast as your polyurethane manufacturing partner, switching to PU becomes a decision that drives long-term operational success.