- info@vampoly.com

- +91-98480-50625

- +91-77990-57575

At Vam Poly Plast, we understand how critical conveyor systems are to industrial operations. From manufacturing plants to logistics centers, conveyors are essential for smooth material handling and uninterrupted productivity. Over the years, we have seen one common issue across industries—frequent wear and failure of conveyor rollers, leading to downtime, high maintenance costs, and reduced efficiency.

This case study highlights how our polyurethane (PU) coated rollers helped a manufacturing unit significantly improve conveyor life, performance, and overall operational efficiency.

One of our clients, a mid-sized industrial manufacturing unit, approached us with recurring conveyor problems. Their existing rollers, made from conventional materials such as rubber and metal, were failing faster than expected due to:

| Continuous heavy loads and friction |

| Exposure to dust, moisture, and chemicals |

| Long operational hours |

| Frequent start-and-stop cycles |

| Frequent roller replacements |

| Increased maintenance expenses |

| Unexpected production downtime |

| Reduced conveyor efficiency |

The client needed a durable, cost-effective solution that could extend roller life without requiring major changes to their existing conveyor system.

After studying the client’s operating conditions and conveyor specifications, we recommended upgrading to our PU coated rollers. Polyurethane is one of our core specializations, known for its exceptional mechanical strength and wear resistance.

We applied high-performance PU coating to the existing roller design, ensuring seamless integration into the conveyor system without any structural modifications.

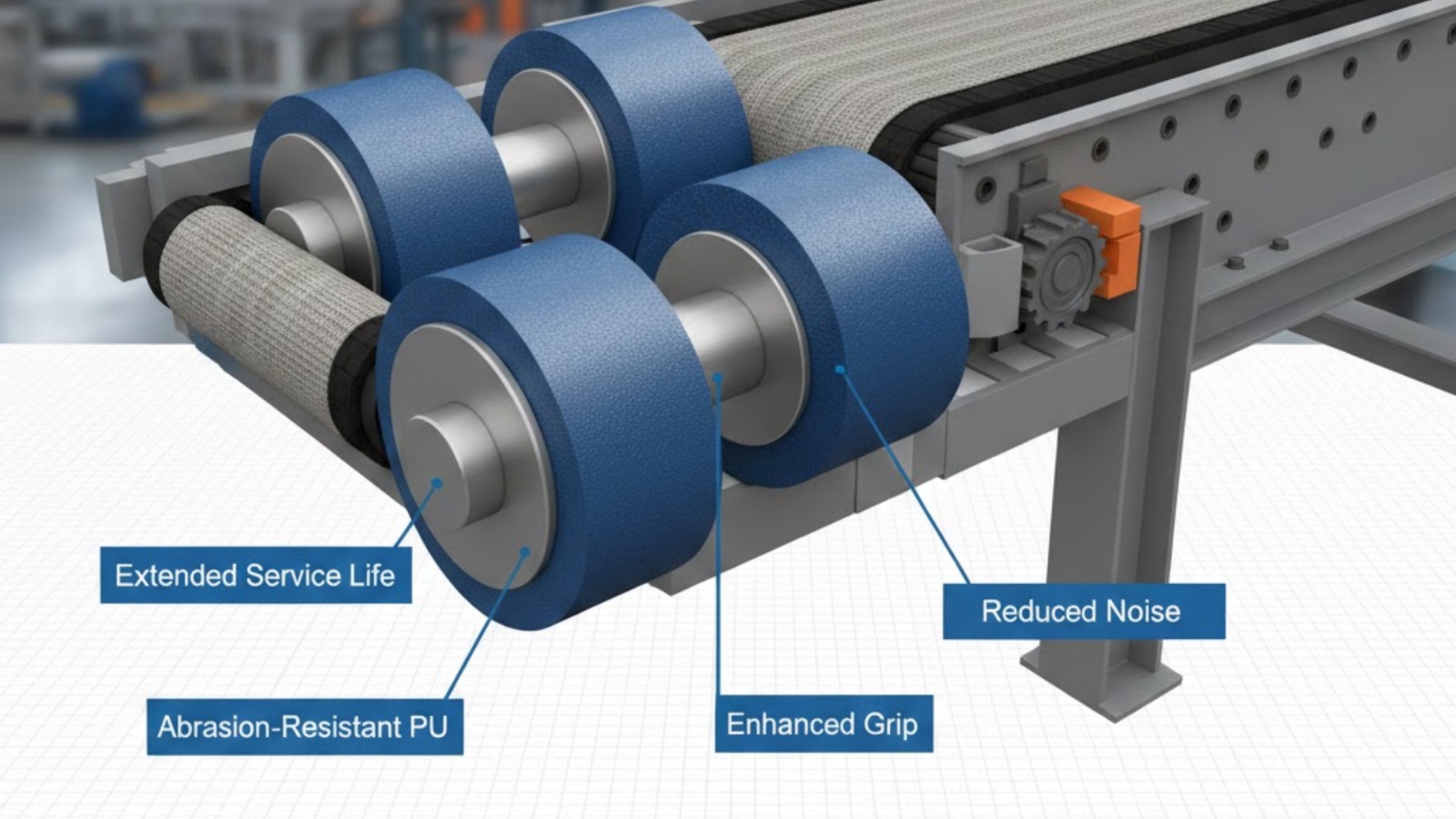

1. Superior Wear Resistance

Our polyurethane coatings provide excellent abrasion resistance compared to rubber and mild steel. This makes our polyurethane coated conveyor rollers ideal for continuous operation and heavy-load applications.

2. Enhanced Roller Durability

Our polyurethane coatings provide excellent abrasion resistance compared to rubber and mild steel. This makes our polyurethane coated conveyor rollers ideal for continuous operation and heavy-load applications.

3. Reduced Noise and Vibration

PU naturally absorbs shock better than metal. By using our PU coated rollers, the client experienced quieter conveyor operation and reduced vibration, improving workplace comfort and reducing stress on conveyor components.

4. Resistance to Chemicals and Moisture

Our polyurethane formulations are resistant to oils, greases, moisture, and many industrial chemicals, making them ideal for demanding environments where traditional materials fail quickly.

5. Cost-Effective Over Time

While PU coated rollers may have a slightly higher initial investment, their long service life and reduced maintenance needs delivered substantial cost savings over time.

At Vam Poly Plast,, we follow a detailed and application-focused approach. For this project, our team:

We manufactured and delivered the rollers within the committed timeline, ensuring minimal disruption to the client’s operations.

After installing our industrial PU coated conveyor rollers, the client reported clear and measurable improvements:

The improved reliability also supported uninterrupted performance during peak production periods.

| Feature | Traditional Materials | PU Coated Rollers |

| Wear Resistance | Moderate to low | High |

| Noise Control | Low | Excellent |

| Chemical Resistance | Limited | High |

| Maintenance Cost | High | Low |

| Service Life | Shorter | Longer |

This comparison clearly demonstrates why polyurethane coated rollers are a smarter long-term investment for modern conveyor systems.

At Vam Poly Plast, we are a trusted manufacturer of polyurethane products in India, offering customized PU solutions for a wide range of industrial applications. Our strengths include:

We focus on delivering solutions that enhance equipment life, reduce downtime, and improve operational efficiency.

This case study showcases how upgrading to PU coated rollers can significantly enhance conveyor performance and lifespan. For industries facing frequent roller failures and rising maintenance costs, polyurethane offers a reliable and cost-effective solution.

By choosing polyurethane coating for conveyor rollers from Vam Poly Plast, businesses can achieve longer service life, smoother operations, and a stronger return on investment.